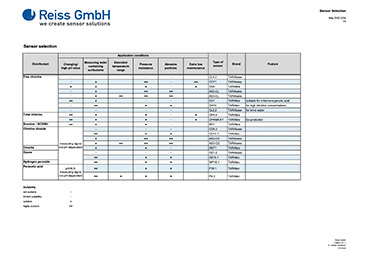

Product information

Sensors

Our sensors are suitable for distillated water, drinking water, pool water, service water, cooling water, CIP-plants, waste water, etc.

The highest resolution is 1 µg/L, the largest measuring range is 10.000 ppm. With a special measuring and control device all the advantages of the sensors can be exhausted. Because of the different electrical types, e.g. 4-20 mA connection or customer specific connections, the sensors can naturally be connected with customer´s measuring and control devices.

The following disinfectants can be measured:

Bromine, Chlorine, Chlorine dioxide, Chlorite, Ozone, Peracetic acid, Hydrogen peroxide.

The manufactoring of our sensors is subjected to rigorous quality inspections, i.e. during the manufacturing process, the individual components are continuously inspected.

Here you can download our current flyer download.

Please also refer to our corporate guidelines.

Brands

TARAeasy

TARAeasy

CCF1: Free chlorine, pH dependent

TARAbase

TARAbase

TARAbase includes all

membrane-covered 2-electrode systems working with the type M20 membrane cap.

The following versions are available:

CL4: Free chlorine, pH dependent

CL2: Free chlorine, pH dependent

CD4: Chlorine dioxide

OZ1: Ozone

TARAline

TARAline

The following versions are available:

CS4: Free chlorine, reduced dependence on pH

CC1: Free chlorine, based on isocyanuric acid, reduced dependence on pH

CP4.0: Total chlorine, reduced dependence on pH

BR1: Free bromine or 1-Bromo-3-chloro-5.5-dimethyl-hydantoin

MST1: Chlorite

TARAtec

TARAtec

TARAtec series “10”: mechanically durable membrane and improved surfactant resistance

TARAtec series “9”: combines the advantages of the 10 series with an increased temperature range up to 60 °C

CD10: Chlorine dioxide

OZ10: Ozone

P10: Peracetic acid

P9: Peracetic acid, max. measuring water temperature 60 °C

WP10: Hydrogen peroxide

CH10: Chlorine

TARAsens

TARAsens

AS2: Free chlorine / chlorine dioxide up to 50°C

AS3: Free chlorine / chlorine dioxide up to 70°C

Technologies

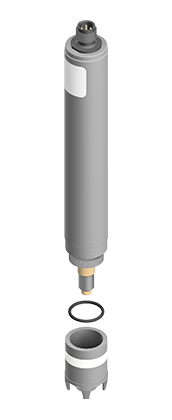

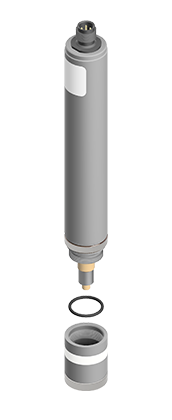

Membrane-covered

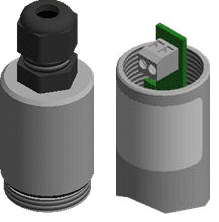

The sensors have a diameter of 25 mm. The sensors equipped with a plug adapter connection have a length of 175 mm. The 4-20 mA models have a length of 220 mm.

The sensors are working with different electrochemical methods of measuring:

Two-electrode system

In this system, the measuring electrode is made of gold, the combined counter and reference electrode is made of silver and has a silver halide coating. Between the two electrodes, a bias voltage (polarisation voltage) is applied.

Three-electrode system

In this potentiostatic system, the measuring electrode is made of gold, the reference electrode is made of silver with a silver halide coating and the counter electrode is made of stainless steel. The measuring electrode is maintained at an appropriate working potential by the potentiostat.

General advantages of the membrane-covered sensor

- It`s handling, set-up and maintenance are extremely simple. The electrode system has a long lifetime, the only part subject to wear and tear being the membrane cap which has to be replaced approximately once a year.

This keeps maintenance costs low. - The run-in period of most sensors is less than one hour.

- No zero point calibration is necessary so that no “zero water” is required.

Due to the single-point adjustment, calibration is fast and easy (only slope calibration required). - Low flow-rate dependance. Variations of the flow-rate have only small influence on the measuring signal.

- A special advantage is the operation of the sensors at a pressure of approx. up to 10 mWC (1 bar) (higher pressures available on request) which allows the simple return of the measuring water.

- The temperature compensation is integrated in each sensor.

- The response time before 90% of the final value is reached, is less than two minutes with almost all types of sensors.

- The long-time stability is very good. The loss in slope is approx. 1% per month.

- The measuring signal has low resistance so that even long measuring lines do not cause any disturbances.

- The sensors are available with various measuring ranges and various power supplies so that they can be adapted to instrumentation and control equipment existing at the customer´s premises. Customer specific types are possible.

- For inspection the sensors can be removed easily and sent back to us.

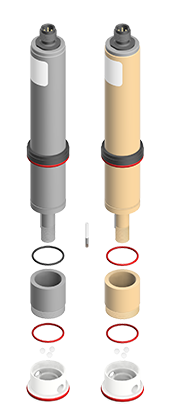

Non-membrane-covered

Sensors TARAsens AS2 and TARAsens AS3

Destroying legionalla pneumophila and removing biofilms building up in hot water pipelines and / or hot water boilers (this is, of course, also true for cold water pipelines) is becoming more and more important. Problems caused by this increasing build-up of germs are present mainly in buildings and institutions having centralised widely-branched water supply systems, like those in hospitals, major hotels, schools, barracks etc.

To obtain proper hygienic conditions, chlorine or chlorine dioxide can be used as disinfectants. The previously used measuring systems for measuring the disinfectant concentration can only be operated without pressure. This means that the measuring water, approx. 30 l/h as a rule, is lost. This continuous loss of (hot) water causes unnecessarily high costs. The outgassing of the (unpressurised) measuring water may also result in measuring problems.

Therefore there was a demand for developing a new sensor to be used especially for the disinfection of drinking water. This sensor TARAsens AS2 can be used for temperatures up to at least 50 °C (TARAsens AS3 70 °C) and at pressures of 8 bar (80 mWC).

The optimum location for the application of the Sensors is the bypass leading to the main water supply line having its own measuring water circulation. The bypass allows maintenance of the sensor, if required, without the necessity to interrupt the entire water supply system.

The TARAsens AS-CL version of the TARAsens AS2-CL and TARAsens AS3-CL is available for chlorine measuring, and the TARAsens AS2-CD and TARAsens AS3-CD is suitable for measuring chlorine dioxide. Due to the different sensitivity, it is essential for the measuring device to have a wide slope adjustment range. It is obvious that only microprocessor controlled measuring devices or controls should be used. A zero-point adjustment is not necessary.

Signal output

0 … -2000 mV

0 … +2000 mV

4-20 mA

Modbus RTU

Electrical connections

Signal output analog

0 … +/-2000 mV

5-pole M12 plug-on flange

(analog or digital internal signal processing)

4-20 mA (uncalibrated)

2-pole terminal

(Analog internal signal processing)

5-pole M12 plug-on flange

(Analog internal signal processing)

Signal output digital

Modbus RTU

5-pole M12 plug-on flange

(Digital internal signal processing)